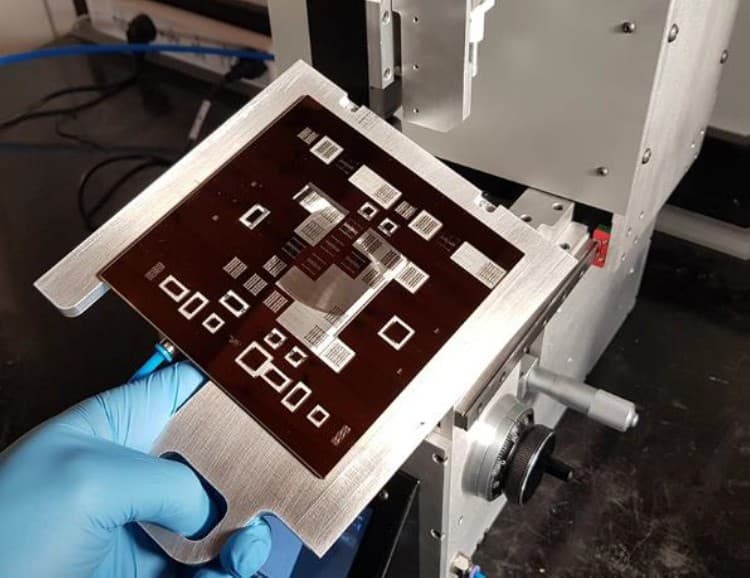

MUTECH Microsystems produce a full suite of microfabrication tools aimed at making cutting-edge technology more accessible for education, research and industry. Through expert, considered design, their systems combine powerful, cutting-edge feature sets with ease-of-use, simple maintenance and reliability.

The current product range includes direct laser lithography equipment, mask aligners, spin coaters, and UV exposer tools.

Key features

- Advanced feature sets

- Compact units for benchtop location

- Turnkey for easy setup

- User-friendly operation and maintenance

- Highly reliable; proven performance

- Cleanroom, glovebox and fumehood compatible

- High value and fast delivery

Applications

- Microelectronics and semiconductors

- MEMS

- Nanotechnology

- Optical and photonic research

- Sensors

- Microfluidics

- Biotechnology