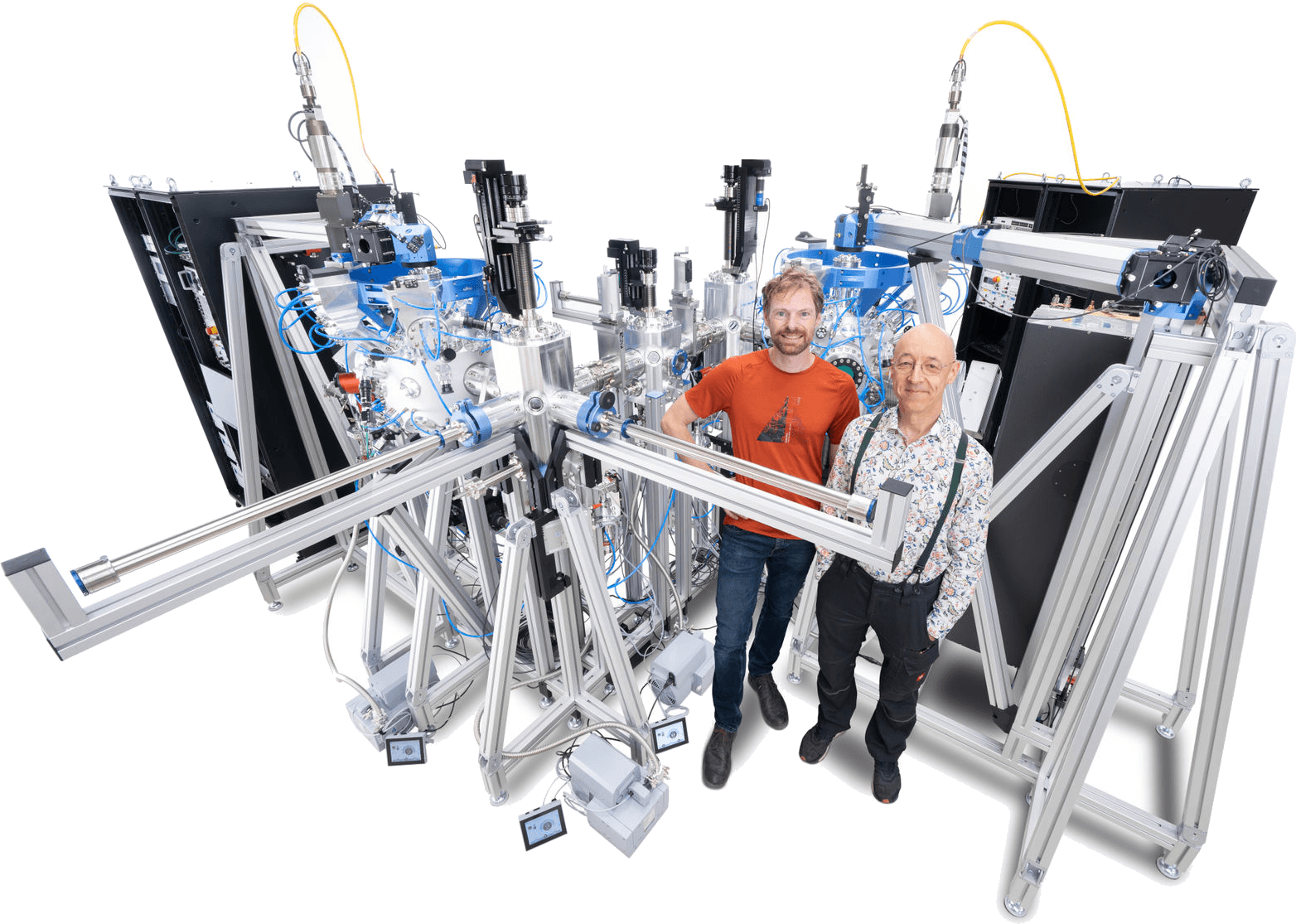

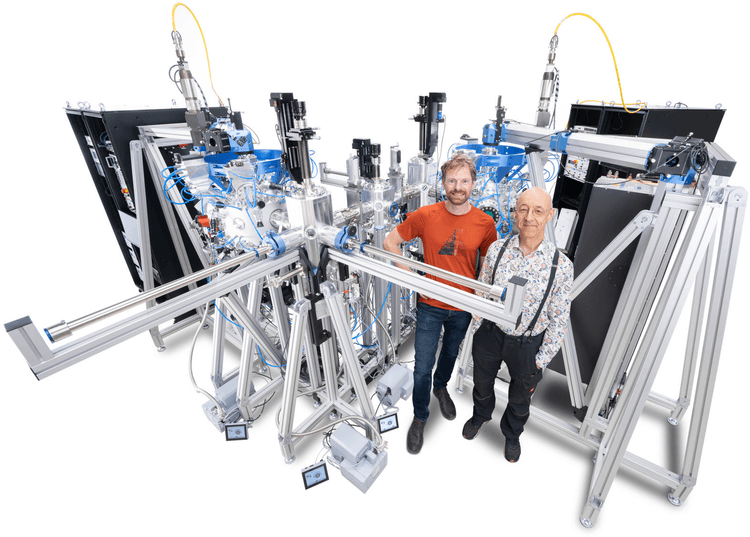

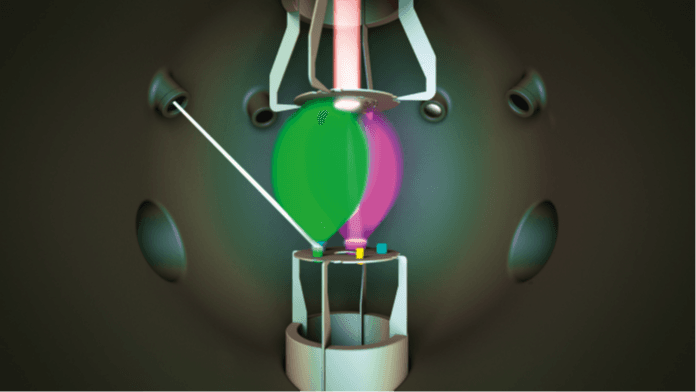

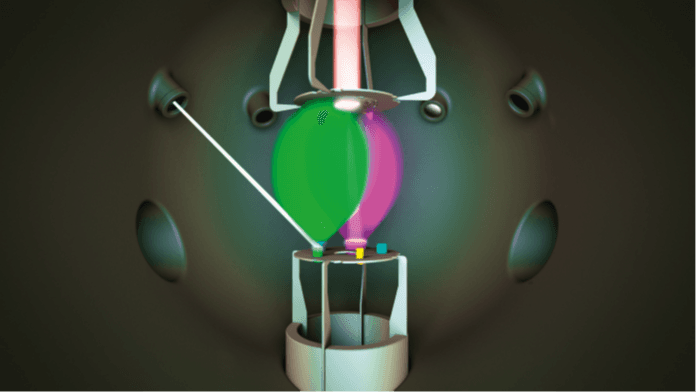

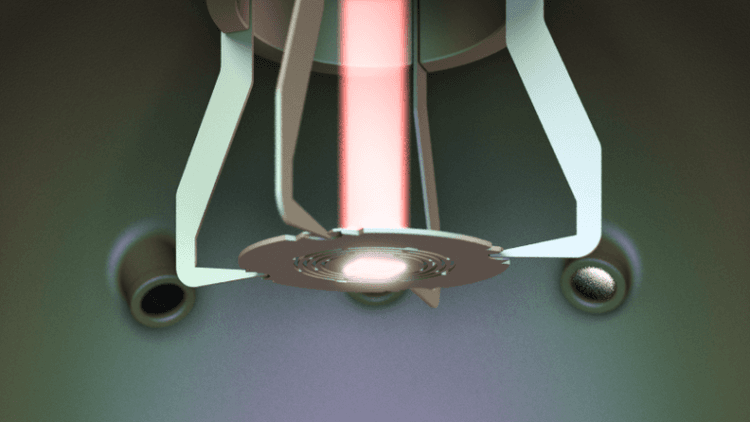

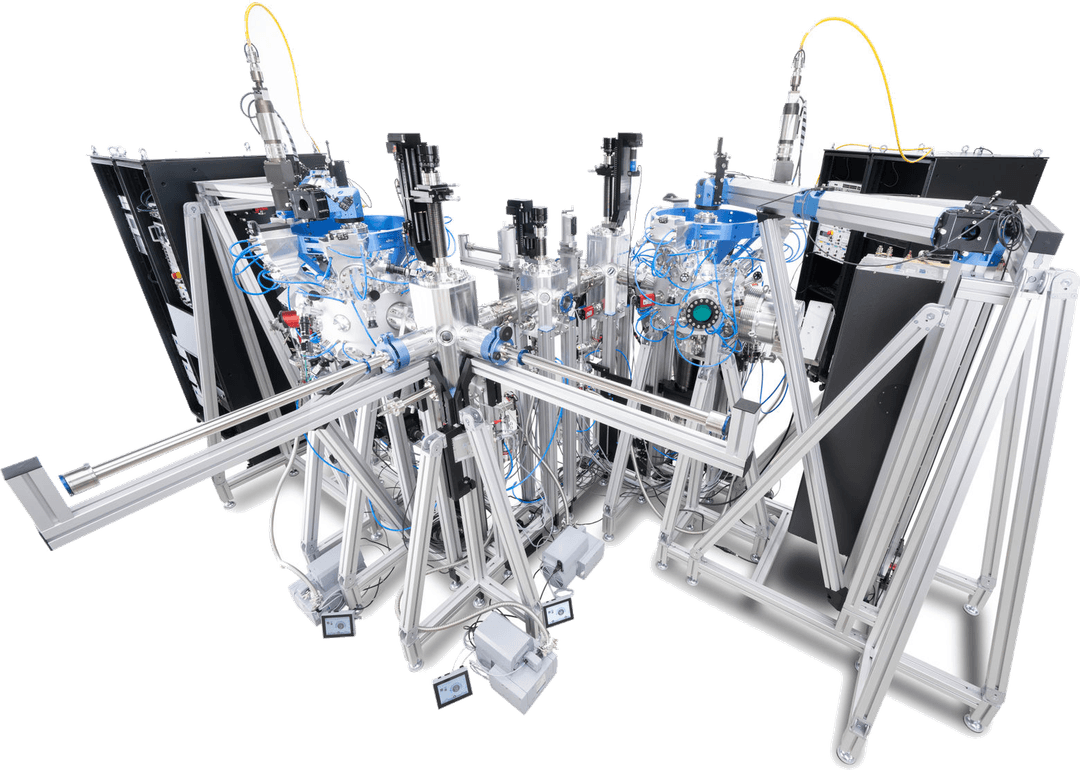

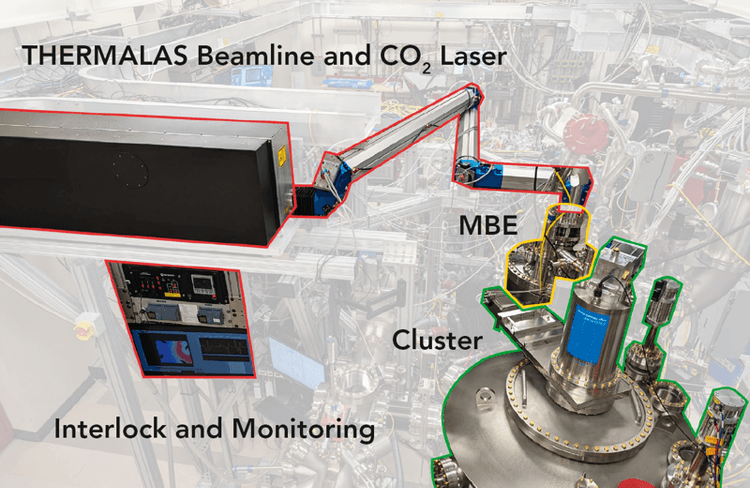

epiray, a spin-off of the Max Planck Society, introduces Thermal Laser Epitaxy (TLE), a revolutionary technology for the deposition of high-purity thin films. TLE is a physical vapor deposition technique that exclusively uses laser beams for heating, enabling the synthesis of superior quality films from virtually any element in the periodic table and in any background atmosphere. This versatile and high-throughput method is poised to significantly impact thin film research and production.

Key features

- Unmatched versatility

- Unlimited temperature range

- Exceptional purity

- High throughput and reproducibility

- Proven performance

Applications

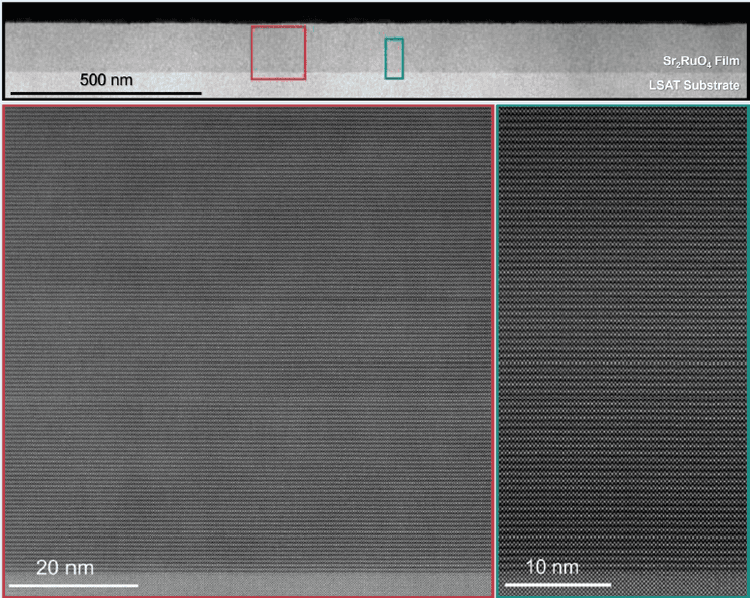

- Superconducting Sr2RuO4

- Epitaxial superconducting nitrides on sapphire, e.g., TiN and NbN

- Nitrides for electronics and magnetics, e.g., GdN and YN

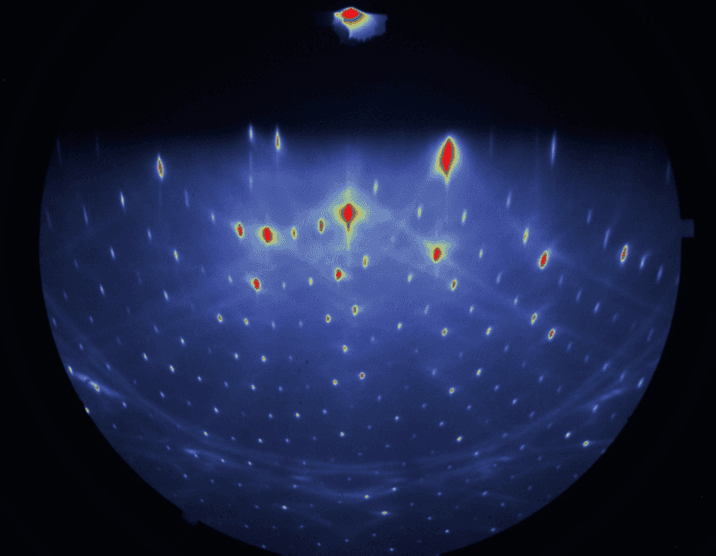

- Fully coherent epitaxial nitride stacks on sapphire

- Ultra-pure oxides and perfect crystals, e .g., perfect sapphire homoepitaxy

- Refractory metal films